Quick Highlights:

- Ford commits $5B to EV production, creating nearly 4,000 U.S. jobs

- New Ford Universal EV Platform reduces parts, costs, and assembly time

- First vehicle: midsize, four-door electric pickup priced around $30,000

- Louisville Assembly Plant receives $1.9B upgrade, adding 2,200 jobs

Ford Bets $5 Billion on America: New Universal EV Platform and Midsize Electric Truck Coming in 2027

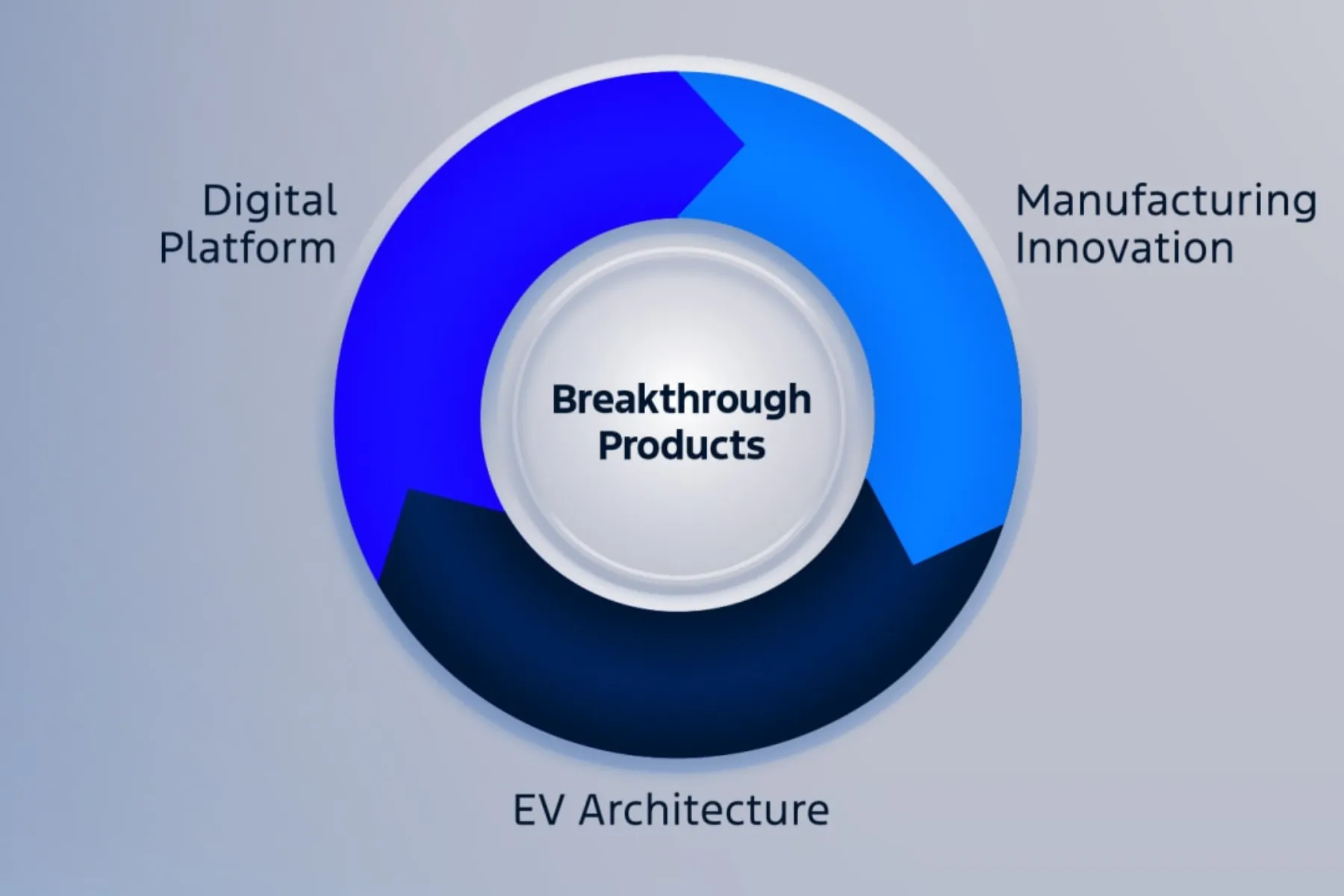

Ford Motor Company is setting the stage for what it calls a “Model-T Moment,” revealing an ambitious $5 billion investment into U.S. manufacturing to produce a new family of affordable, high-quality electric vehicles. Central to the plan are the Ford Universal EV Platform and Ford Universal EV Production System—innovations designed to radically streamline vehicle assembly while enhancing performance, cost efficiency, and driving enjoyment.

The first vehicle in this lineup will be a midsized, four-door electric pickup truck, slated for assembly at the Louisville Assembly Plant (LAP) in Kentucky starting in 2027. With a targeted starting price of about $30,000 and performance rivaling the Mustang EcoBoost, the truck is expected to combine affordability, utility, and driving excitement.

Ford’s total investment includes $1.9 billion dedicated to upgrading the Louisville Assembly Plant, creating 2,200 full-time jobs. An additional $3 billion will go to BlueOval Battery Park Michigan, where Ford will produce advanced prismatic lithium iron phosphate (LFP) batteries. Combined, these projects are expected to create or secure nearly 4,000 U.S. jobs.

Revolutionizing EV Design: The Ford Universal EV Platform

The Ford Universal EV Platform is engineered for efficiency and affordability. Ford says it will reduce the number of parts in a typical vehicle by 20% and use 25% fewer fasteners. Production lines will have 40% fewer workstations, resulting in a 15% faster assembly time.

Key benefits include:

- Lower ownership costs over five years than a three-year-old used Tesla Model Y

- Shorter and lighter wiring harnesses—over 4,000 feet shorter and 10 kilograms lighter than first-generation electric SUVs

- Structural, cobalt-free, nickel-free prismatic LFP battery pack that doubles as the vehicle’s floor, improving handling and interior space

The new midsize electric truck is forecasted to offer more passenger space than the latest Toyota RAV4, plus the added storage of both a frunk and a lockable truck bed. The low center of gravity from the battery pack will enhance stability and ride comfort, while instant electric torque and precision chassis engineering promise an engaging driving experience.

Doug Field, Ford’s chief EV, digital, and design officer, emphasized that this platform is far from a cost-cutting compromise: “We applied first-principles engineering, pushing the limits of physics to make it fun to drive and compete on affordability. This isn’t a stripped-down, old-school vehicle.”

Rethinking the Assembly Line: The Ford Universal EV Production System

More than a century after Ford pioneered the moving assembly line, the company is introducing the Ford Universal EV Production System—an “assembly tree” concept that allows three major sub-assemblies to be built simultaneously before coming together into a finished vehicle.

Highlights of the new production method include:

- Large single-piece aluminum unicastings replacing dozens of smaller components

- Front and rear sections built separately before joining with the structural battery assembly

- Kits containing all parts, tools, and fasteners needed for each workstation, improving ergonomics and reducing strain on workers

- Up to 40% faster assembly time compared to current Louisville Assembly Plant vehicles, with a net 15% speed improvement after reinvesting time into quality and automation

Bryce Currie, Ford vice president of Americas Manufacturing, explained, “We put our employees at the center and re-created the factory from scratch. We expect ergonomic breakthroughs and complexity reduction to lead directly to quality and cost improvements.”

Louisville Assembly Plant: $1.9 Billion Transformation

The Louisville Assembly Plant will see a major overhaul to prepare for the new midsize electric truck. The facility will expand by 52,000 square feet to improve material flow, and receive digital infrastructure upgrades that will make it the fastest networked Ford plant worldwide. This will allow for increased quality scanning and real-time data sharing across the production process.

Kentucky Gov. Andy Beshear praised the move, noting that the investment represents one of the largest in the state’s history. “Ford and Team Kentucky are introducing the world to the future of automotive production… securing 2,200 jobs for Kentuckians and solidifying Louisville Assembly Plant as an important part of Ford’s future,” Beshear said.

Battery Innovation at BlueOval Battery Park Michigan

Ford’s $3 billion investment in BlueOval Battery Park Michigan will make it the first automaker to produce prismatic LFP batteries in the United States. These batteries offer significant cost savings and increased durability, while also reducing reliance on expensive materials like cobalt and nickel.

Production is expected to begin next year, with the batteries destined for the new midsize pickup and future EV models. This move will strengthen the domestic supply chain and create opportunities for dozens of new U.S.-based suppliers.

Model-T Inspiration for the EV Era

Ford executives have been clear that this initiative is designed to be more than another EV announcement—it’s meant to reshape how affordable electric vehicles are engineered and built. President and CEO Jim Farley stated, “We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers… and do it with American workers.”

The strategy mirrors the disruptive impact of the original Model T, which revolutionized mobility in the early 20th century by making cars accessible to the masses. Now, Ford aims to make EVs just as attainable, with advanced software capabilities, over-the-air updates, and zonal electric architecture that unlocks new digital features.

Looking Ahead to 2027

Ford has yet to reveal key specifications for the midsize electric pickup—such as battery range, charge times, and exact launch date—but promises more details closer to production. The company has positioned the truck as a practical, performance-oriented option for everyday drivers, with a price point designed to appeal to a wide customer base.

By merging advanced manufacturing with cutting-edge battery technology and a focus on worker ergonomics, Ford is betting big on an American-built EV future. With nearly $5 billion invested and thousands of jobs created, the company’s Universal EV Platform and Production System may become the blueprint for affordable electric mobility in the years ahead.