Cathode Innovation Emerges as the Real Solid-State Breakthrough

At the Third China Solid-State Battery Innovation Summit in Beijing earlier this month, industry leaders delivered a clear message: the future of solid-state batteries depends more on cathode innovation than electrolyte breakthroughs.

Professor Xia Dingguo of Peking University emphasized that energy density — largely dictated by the cathode — is the core metric that will determine whether solid-state batteries transition from laboratory research to commercial production. While electrolytes often dominate headlines, experts at the summit argued that without significant advances in cathode materials, industrial-scale impact will remain limited.

From my perspective, this shifts the conversation in a meaningful way. For years, solid electrolytes were treated as the primary bottleneck. Now, the spotlight is turning to the component that ultimately controls performance, cost, and long-term viability.

Also Read: Solid-State Batteries - A Reality Check for EV Buyers

Why Solid-State Batteries Are Back in Focus

The renewed momentum behind solid-state batteries stems from two major developments:

Stronger research capabilities compared to the 1990s

Rising EV demand for higher energy density, improved safety, and material efficiency

Automakers and battery manufacturers are under pressure to deliver longer driving range, enhanced thermal stability, and lower lifecycle costs. Solid-state batteries promise all three — at least in theory.

However, summit experts cautioned that without cathode breakthroughs, these promises cannot translate into large-scale industrial relevance.

The Core Technical Challenges

1. Interface Stability Issues

One of the most pressing obstacles is interface instability between cathodes and solid electrolytes.

Experiments using high-nickel cathodes show improved thermal stability, yet safety concerns persist under high current and voltage conditions. The key problems include:

- Local polarization

- Formation of high-impedance interfacial layers

- Gradual performance degradation

Fluorine doping can temporarily stabilize cycling performance, but degradation accelerates after roughly 125 cycles, limiting long-term reliability.

Another complication lies in the crystalline nature of cathode materials. Because they are anisotropic, even small volume changes can concentrate stress at material interfaces, significantly reducing cycle life.

Also Read: What Makes BYD’s Blade Battery Technology so Different?

.webp)

2. Material Compatibility Constraints

Material compatibility between cathodes and different solid electrolytes further complicates commercialization.

Current electrolyte options include:

- Chlorides

- Sulfides

- Oxides

Each comes with trade-offs:

- Oxide electrolytes are mechanically rigid, making interface management difficult.

- Sulfide and chloride electrolytes often require applied pressure to function effectively, complicating manufacturing processes.

Experts suggested that progress may depend on low-modulus, interface-friendly electrolytes or optimized polymers capable of wide voltage windows and high ionic conductivity.

In my view, this highlights a broader theme: the challenge isn’t just material discovery — it’s ensuring compatibility within a scalable manufacturing environment.

Also Read: MG’s Semi-Solid-State Battery is a Game Changer for EVs

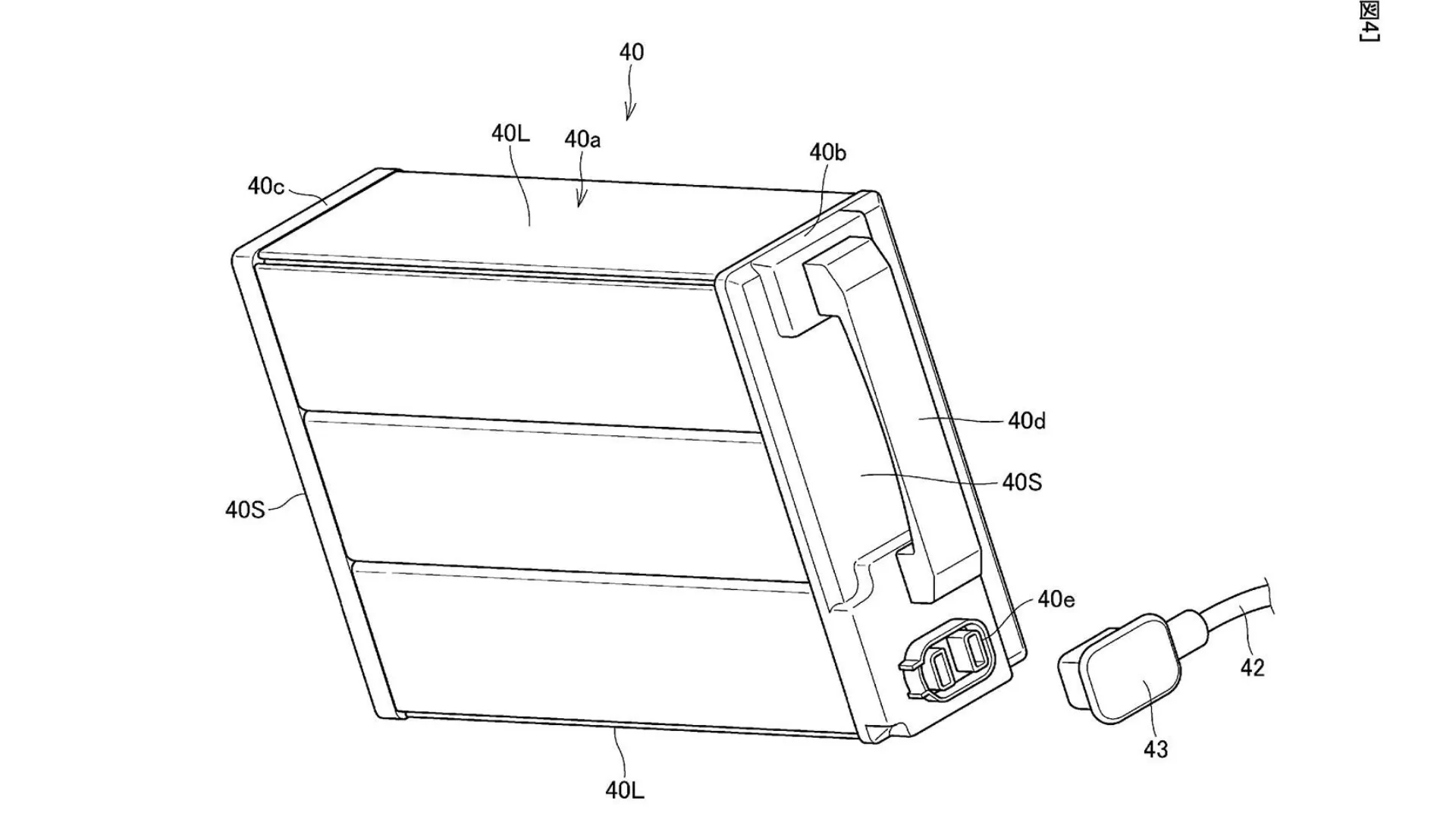

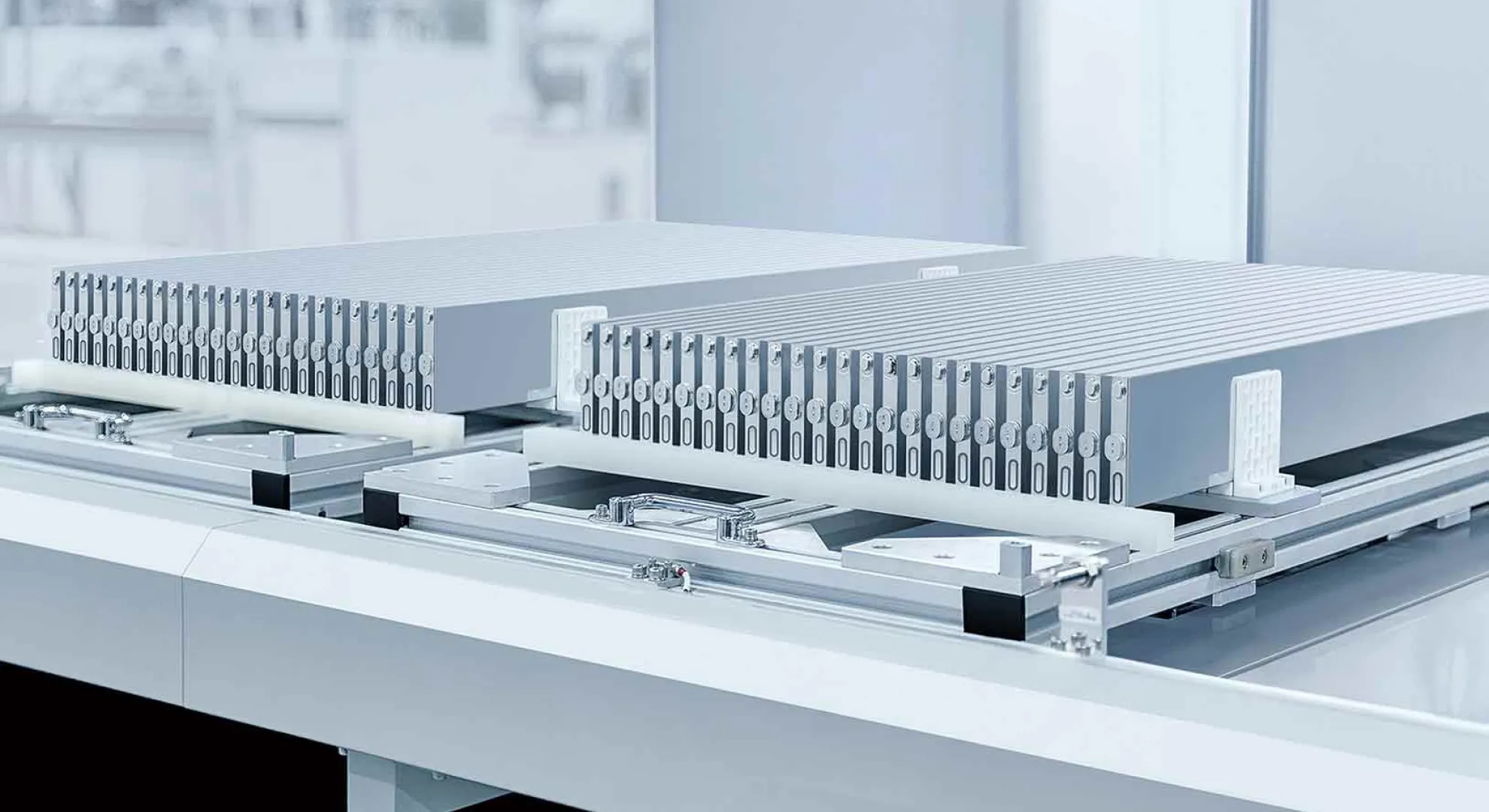

China’s Battery Leaders Move Toward Integrated Development

Major Chinese battery manufacturers — including CATL, BYD, and Eve Energy — are already adapting.

Rather than treating cathodes and electrolytes as separate research tracks, they are pursuing integrated system development, aiming to:

- Optimize cell-level performance

- Build patent protection portfolios

- Improve manufacturability

Manufacturing innovations such as dry electrode processes, co-sintering, and cold sintering are also advancing. These approaches reduce reliance on complex coating processes and move the industry closer to scalable production.

A Segmented Future for Solid-State Batteries

The summit concluded that solid-state battery development will likely follow diversified application paths:

High-End EVs

- Polymer electrolytes

- High-nickel or lithium-rich cathodes

- Focus on maximum energy density

Mass-Market EVs

- LiFePO4 systems

- Prioritize safety and cost efficiency

Specialized Applications

- Sulfide electrolytes paired with sulfur cathodes

This segmentation reflects practical market realities. Not every EV segment requires cutting-edge density; some prioritize affordability and safety.

Also Read: Verge Motorcycles Unveils World’s First Electric Bike With Solid-State Battery

Cathodes: The “Bull’s Nose” of Industrialization

Experts at the summit described cathode material innovation as the “bull’s nose” of solid-state battery industrialization — meaning it is the central lever that drives progress.

Electrolytes remain important, but energy density, cost structure, and long-term stability fundamentally hinge on cathode development.

Looking ahead, sustained leadership in the global solid-state battery sector will require parallel advances in material science and manufacturing engineering. In my view, the companies that successfully integrate both will define the next generation of EV power systems.

Frequently Asked Questions — FAQs

Q. Why are cathodes more important than electrolytes in solid-state batteries?

- Cathodes largely determine energy density, cost, and long-term performance. While electrolytes influence safety and stability, overall battery capacity and commercial viability depend heavily on cathode innovation.

Q. What are the main challenges facing solid-state battery commercialization?

- The biggest challenges include interface instability, material compatibility, limited cycle life, and manufacturing complexity.

Q. Which companies are leading solid-state battery development in China?

- Major players include CATL, BYD, and Eve Energy, all of which are pursuing integrated cathode–electrolyte development strategies.

Q. Are solid-state batteries ready for mass-market EVs?

- Not yet at full scale. High-end models may adopt advanced chemistries first, while mass-market EVs are expected to prioritize safer and more cost-effective systems like LiFePO4.

Q. What role does energy density play in EV battery innovation?

- Energy density directly affects driving range and battery weight. Improvements in cathode materials are essential to achieving higher energy density without compromising safety or cost.